Steeltec’s high-strength steel grades ETG® and HSX® now available as precision-finished lengths

Steeltec’s high-strength steel grades ETG® and HSX® now available as precision-finished lengths

With SCHMOLZ + BICKENBACH's bright bar activities now pooled under the Steeltec name, Steeltec is now able to offer its customers precision-finished lengths of its high-strength and higher strength special steel. Companies supplying components to the automotive and mechanical engineering industries can now obtain precision-finished lengths of Steeltec’s market-leading special steel grades ETG® and HSX®. ETG® and HSX® are characterised by their high strength and excellent machinability and are thus particularly well suited for the manufacture of highly stressed precision parts in the mechanical and automotive engineering sectors. Thanks to the upstream material processing that Steeltec performs on its bar steel products, component suppliers to the automotive and mechanical engineering industries are able to focus fully on their core competence in component production. Steeltec’s just-in-time production strategy also means that these suppliers do not need to worry about stock management issues, thus reducing capital costs.

‘The Steeltec site in Düsseldorf is our specialist for producing precision-finished lengths,’ explains Gerd Münch, the CEO of Steeltec. ‘As a result of the recent pooling of the bright bar activities within the SCHMOLZ + BICKENBACH Group, we are now able to offer our customers precision-finished lengths of the high-strength and higher strength special steel ETG® and HSX®.’ These steel grades are characterised by high strength and excellent machinability and as such are suitable for highly stressed precision parts in mechanical and automotive engineering applications. Steeltec’s precision-finishing services cover all of the preparatory processing stages for steel bar, from simple bar cutting operations, to semi-finished products or fully finished, ready-to-install components. These services are available to turning and forging shops as well as to component suppliers for the automotive and mechanical engineering industries throughout Europe. Examples include pre-finished drive shafts, brake pedal pushrods or steel stock of precisely specified weight from which impact-extruded parts can be manufactured, such as housings and preforms or nozzle supports for fuel-injection systems. By outsourcing preparatory processing work to Steeltec, customers are able to reduce costs, e.g. by saving the cost of investing in and maintaining expensive equipment. Customers also require less production space and a smaller workforce.

With its advanced steel processing equipment, Steeltec offers customers throughout Europe a comprehensive range of processing and finishing operations (sawing, lathe turning, chamfering, centring, facing, chip-free washing and deburring). By selecting the bar finishing operations that Steeltec performs, customers are able to immediately begin their own manufacturing and fabrication processes on the material supplied. At Steeltec precision is key. For customers to be able to benefit from smooth stock feeding into their automated machine tools, the stock supplied has to be dimensionally precise. If requested, Steeltec can supply its products to tight design tolerances up to ISO tolerance grade IT 6. End machining and end-face stamping of the bar material is carried out in accordance with customer drawings, so that the bright steel bars can be guided smoothly and accurately into the CNC machining centres. With its large pool of advanced metal processing machinery, optimised process control and process monitoring, and its highly trained workforce, Steeltec consistently meets customer requirements regarding quality and supply reliability. If requested, Steeltec’s fully automated packing systems can pack the precision-finished lengths as a bulk goods consignment or can place the bars in layers inside the customers’ own containers.

Figure 1: High-performance metal saw (source: Steeltec)

Figure 2: Example applications in the automotive industry (source: Steeltec)

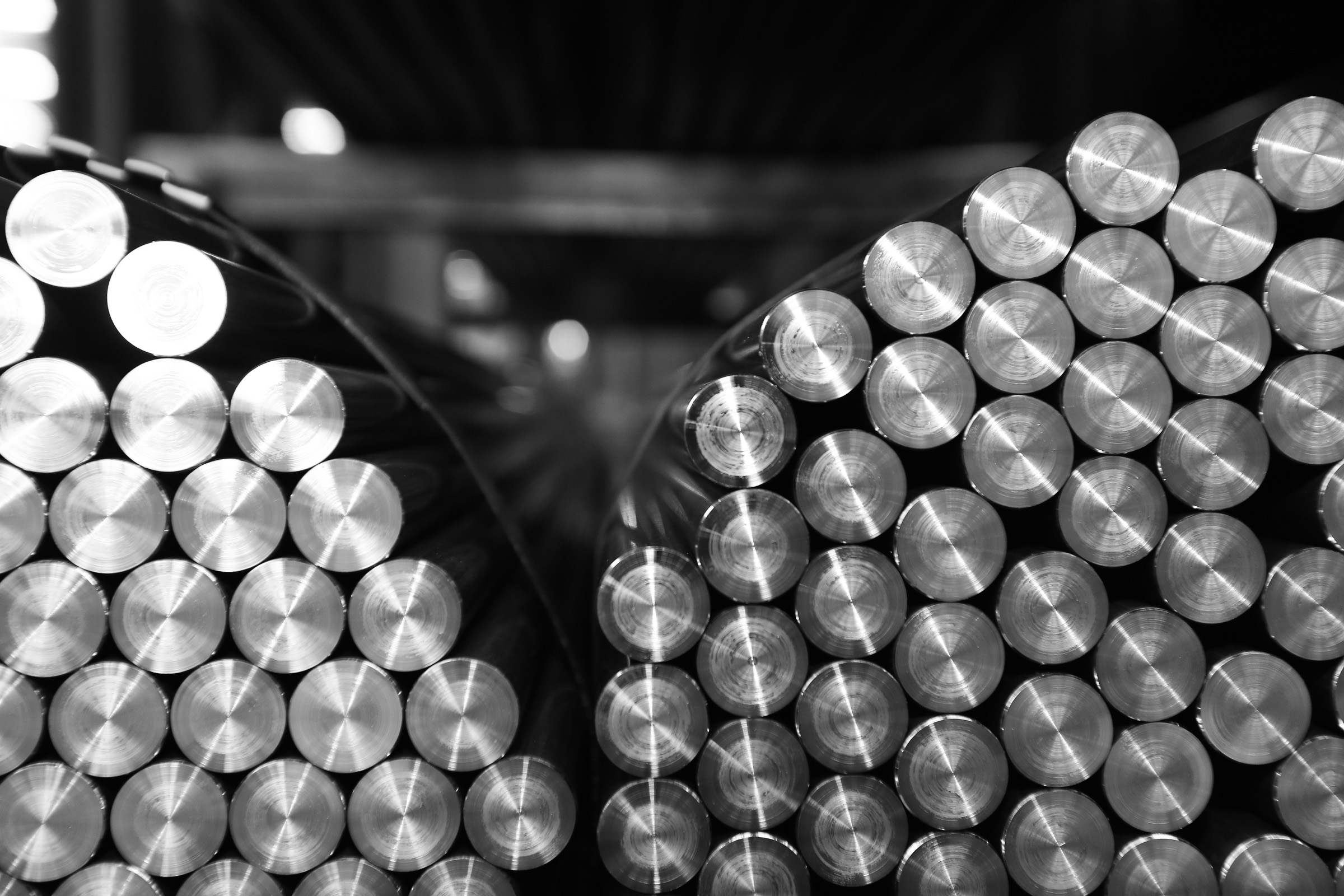

Figure 3: Special bright steel (source: Steeltec)

About the Steeltec Group

With a workforce of around 620 in six locations in Denmark, Germany, Sweden, Switzerland and Turkey, the Steeltec Group is one of Europe’s leading manufacturers of special bright steel. Steeltec’s four self-owned production centres fabricate high-strength and higher strength special steel, high-quality bright steel, special quenched and tempered steel, free-cutting steel, case-hardening steel and engineering steel. Core areas of expertise include the application-specific development and production of high-quality bright steel, precision finishing operations and professional technical advice that is provided locally. The Steeltec Group works closely with customers, suppliers and research institutions to continually improve the production and engineering properties of steel, driving competitiveness across the entire value chain. Thanks to its Europe-wide distribution network, Steeltec can guarantee delivery reliability to its customers in the automotive, hydraulic and mechanical engineering industries.

About SCHMOLZ + BICKENBACH

Today, the SCHMOLZ + BICKENBACH Group is one of the world’s leading providers of customised solutions in the specialty steel long products business. A global name in tool steel and stainless long steel, the Group is one of two largest companies in Europe for alloy and high-alloy engineering steel. With around 9.000 employees at its own production and distribution companies in 35 countries across five continents, the Company supports and supplies customers wherever they operate. Besides the comprehensive Production and Sales & Services portfolio, customers benefit from the Company’s technological expertise, consistent high quality worldwide and in-depth knowledge of local markets.

Corporate Contacts

Elke Schubert • Steeltec GmbH

Phone: +49 211 509 2320 • Fax: +49 211 509 1320

E-Mail: elke.schubert(at)steeltec-group.com

Internet: www.steeltec-group.com

Gerd Münch • Steeltec Group

Phone: +41 (0) 41 209 56 22 • Fax: +41 (0) 41 209 56 05

E-Mail: gerd.muench@steeltec.ch • Internet: www.steeltec.ch

Stefanie Steiner • SCHMOLZ + BICKENBACH

Phone: +41 (0)41 209-5042 • Fax: +41 (0)41 209-5043

E-mail: s.steiner(at)schmolz-bickenbach.com

Internet: www.schmolz-bickenbach.com

External media contact

Hanna Maurer • additiv pr GmbH & Co. KG

Public relations for logistics, steel, industrial commodities and IT

Herzog-Adolf-Straße 3 • D-56410 Montabaur

Phone: +49 (0)2602 950-99 15 • Fax: +49 (0)2602 950-99 17

E-mail: hm@additiv-pr.de • Internet: www.additiv-pr.de