Automotive engineering: Special Q&T steel moves into the fast lane

Induction hardening and tempering of individual steel bars – homogeneity is the key

By subjecting single steel bars to controlled induction hardening, quenching and tempering, the microstructure and material properties of each individual bar can be carefully adjusted enabling continuous production of premium quality steel that exploits the full potential of the material. The result is high-strength, high-performance steel, with each bar and each production batch exhibiting uniform mechanical properties. Carrying out a carefully monitored quench-and-temper (Q&T) cycle on individual bars yields a product that meets the stringent demands of the automotive industry – demands that are set to become even stricter as a result of tighter DIN tolerances and standards. Such precise control of the steel’s properties would simply not be achievable if the bars were subjected to bulk quench and tempering in a furnace. The recipe for reproducing steel bars that have exactly the required mechanical attributes is a combination of Steeltec’s profound understanding of the steelmaking process and its use of the latest production technology.

Precision is the top priority when fabricating components for the automotive sector. Industry preference is increasingly for components that are lighter and more compact. At the same time, these compact small-diameter components are expected to withstand increasingly powerful stress cycles. If these components are to improve vehicle efficiency, and thus effectively reduce its carbon emissions, they have to be designed and dimensioned very precisely. Component manufacturers need to know that the steel they are supplied with is always of the same high quality and that it can be machined or otherwise processed with absolute reliability. That is the ideal. In reality, however, the crux of the matter often proves to be the steelmaking process itself. Quenched and tempered steel is frequently the material of choice for the highly stressed components used in the automotive industry. In many cases, the mechanical properties of the steel are adjusted during a bulk Q&T process. However, there are a number of disadvantages when steel is hardened, quenched and tempered in a bulk operation rather than by treating the individual bars. Steeltec – a company within the SCHMOLZ + BICKENBACH Group – understands the risks associated with bulk heat-treatment and it knows how these risks can be avoided. One of Steeltec’s areas of expertise is in the production of high-performance steel – an area in which it has an excellent understanding of the technical details of the production process. ‘Bulk heat-treatment produces differences between the interior of the bar and the surface of the bar and between the beginning and end of the bar. In many cases, these differences are simply too great when the material is to be used to manufacture high-performance safety-related components,’ explains Thorsten Müller, Head of the Heat Treatment unit at Steeltec’s Düsseldorf site. If the steel is subjected to bulk heat-treatment, the scatter in the strength values is about 150 MPa and the material’s microstructure may also be inhomogeneous. The shackles used to attach the leaf springs that support the axle in semi-trailer suspension systems need to be able to withstand a specific range of permanent loads. If the required strength and toughness values are not distributed evenly over the entire component, the component could, in the worst case, fail, potentially leading to expensive and damaging product recall campaigns.

The solution is to give top priority to each individual bar

‘Tolerances are being continuously tightened by companies in the automotive and mechanical engineering sectors,’ says Thorsten Müller. ‘For a producer of special steels to be seen as a major driver of innovation in the field requires both production expertise and modern technology.’ As one of the leading producers of special bright steel in Europe, Steeltec operates a single-bar heat-treatment line at its Düsseldorf site. Each bar is subjected to individually controlled heating, quenching and tempering. The continuous rotating feed mechanism ensures that each bar is heated evenly, gradually improving the mechanical properties of the steel until the required quality level has been achieved. This also helps to improve bar straightness. ‘We measure and monitor the feed velocity using a laser that is integrated into the heat-treatment line. Any problems, such as a bar becoming jammed in the heat-treatment line, are immediately flagged up,’ explains Müller. ‘We can therefore kill several birds with one stone, so to speak: We not only have an efficient means of avoiding technical defects in the material, but we can also maintain a constant feed rate and thus a uniformly high product quality level.’ All of the relevant process parameters, such as the optimum temperatures for hardening, quenching and tempering and the ideal feed velocity, are stored in a database. Whenever a new or modified steel is to be processed in the heat-treatment line, Steeltec carries out lab studies to determine the necessary adjustments to the process parameters so that the desired microstructure and mechanical properties are attained. Automation also enhances product traceability. If the bars passing through the heat-treatment rig require mandatory documentation, as is the case for materials used in the automotive sector, Steeltec is able to provide comprehensive verification of the steel properties.

Premium quality steel bars up to 13 metres in length

The bars are individually fed in to the heat-treatment line via a worktable that is 13 metres long. Steeltec can therefore process bars with lengths ranging from 2.80 metres to 13 metres. Steeltec matches the size of the induction heating coil to the diameter of the round steel bar being processed. Three different coil sizes from 15 mm up to 80 mm are available. Selecting a coil that closely fits the diameter of the steel bar increases the efficiency of the non-contact induction heating process. ‘Choosing the coil of best fit improves energy efficiency, as less electrical power is lost, which is an important criterion in our energy management system,’ says Thorsten Müller. ‘It also means that the heat-treatment process can be carried out even more precisely, which helps to enhance the quality of our steel products.’ Technical details such as these enable Steeltec to conduct induction hardening and tempering of individual steel bars across the entire dimensional range from 15 mm to 80 mm. The company’s service portfolio also includes the heat-treatment of steel tubes, where again the key feature is the uniformity and precision of the process. The heat-treatment line is equipped with two pipe-lifting levers that enable the quenching medium to be drained from the tubes, thus ensuring that the microstructure is homogeneous, that the mechanical properties are uniformly distributed and that the tubes are straight.

The pressure in the ring jets that spray quenching medium at the steel after hardening is carefully controlled by a flow meter. After quenching, the bar is then tempered. Here, too, induction heating is used. In order to further optimise the physical properties of the steel, the heat-treatment line is configured so that each bar can, if desired, be subjected to additional controlled uniform quenching. As a result of the rapid heating, fast quenching and the high pressure generated by the ring jets, the individual steel bars processed in the Düsseldorf line do not suffer from excessive decarburisation or scaling. Ensuring that all steps are carried out evenly and uniformly effectively prevents mechanical distortion of the bars.

No compromises on quality

A further special feature of the single-bar heat-treatment line in Düsseldorf is the two saws that are installed on the cooling bed. Thorsten Müller explains the need for the integrated saws as follows: ‘Some materials have a tendency to flake or spall at the ends of the bars. In the worst case, these surface defects can cause damage to the tools or sensors used in downstream processing.’ To reduce the risk of this type of damage, Steeltec can automatically cut off a short section at the beginning and end of each bar immediately after it has undergone heat-treatment. Finally, the bars are carefully collected and stored in bundles. ‘Our extensive experience in the induction hardening, quenching and tempering of individual steel bars has been the basis for the continuous optimisation of our heat-treatment system, and will continue to drive further improvements in future,’ says Thorsten Müller in summary. A new advanced heat-treatment line is due to go on stream in 2016, promising precision manufactured, high-performance steel bars of even greater quality.

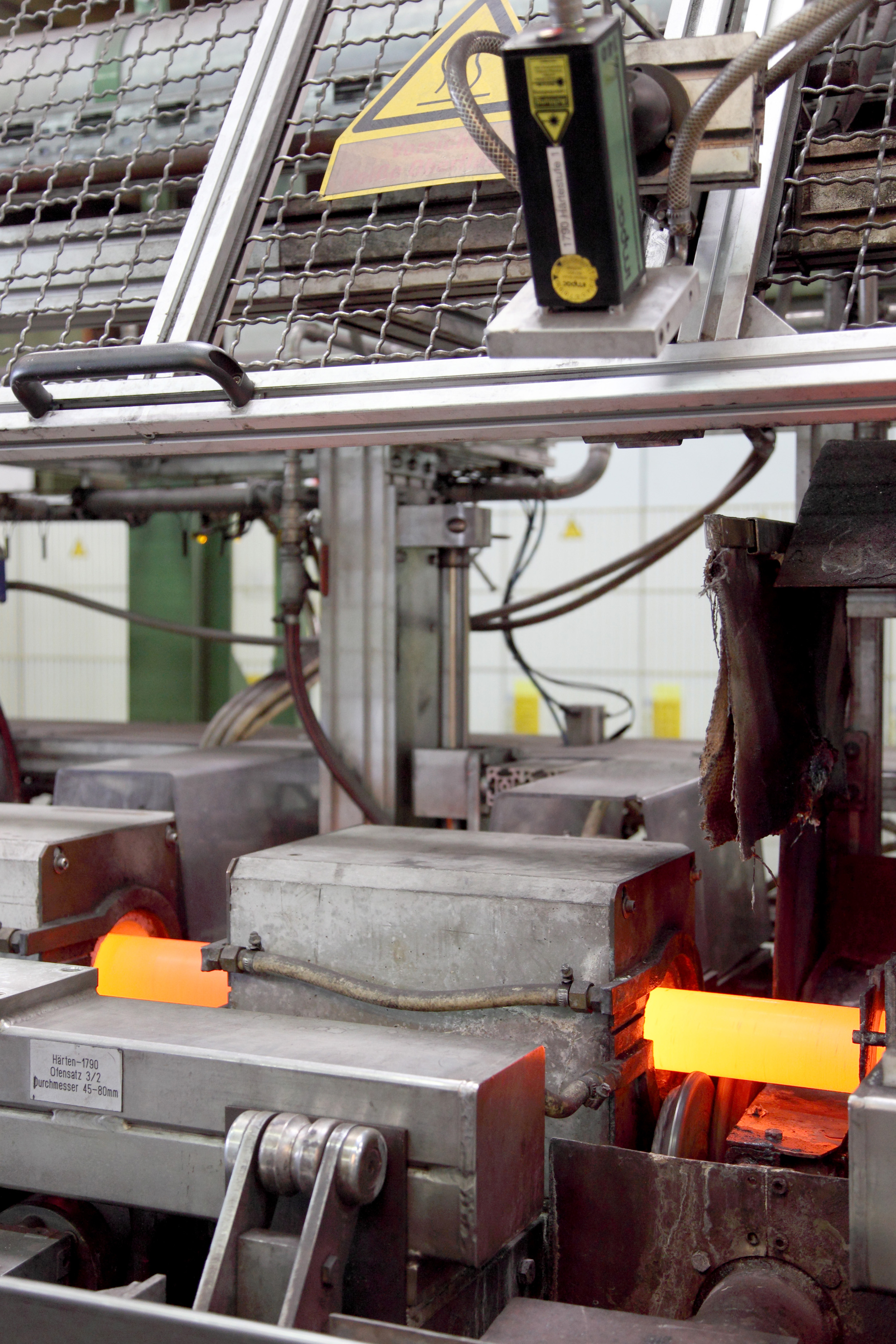

Figure 1: View of the hardening stage, Source: Steeltec, Germany

Figure 2: Induction hardening coil, Source: Steeltec, Germany

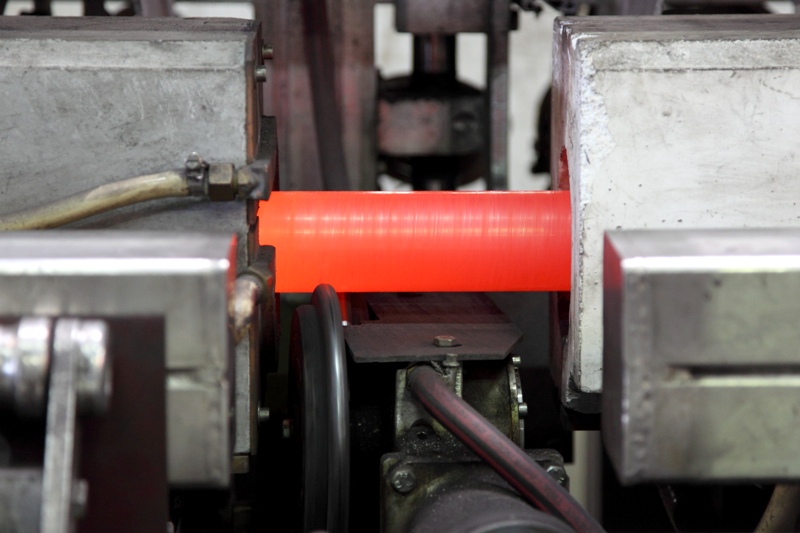

Figure 3: Bar material between two coils, Source: Steeltec, Germany

Figure 4: Transitioning from the final coil to the water quenching zone, Source: Steeltec, Germany

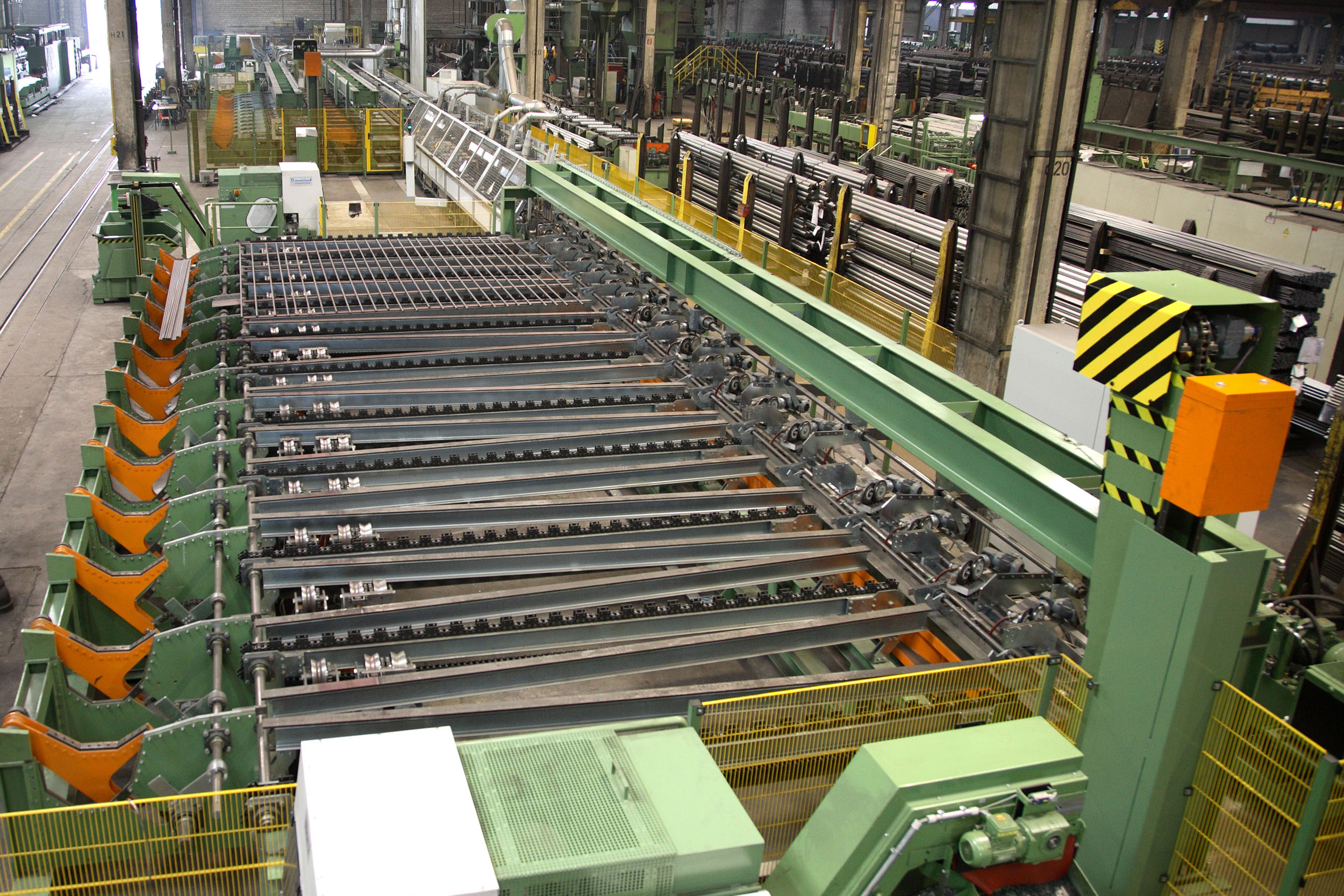

Figure 5: Heat-treatment line showing cooling bed in front, Source: Steeltec, Germany

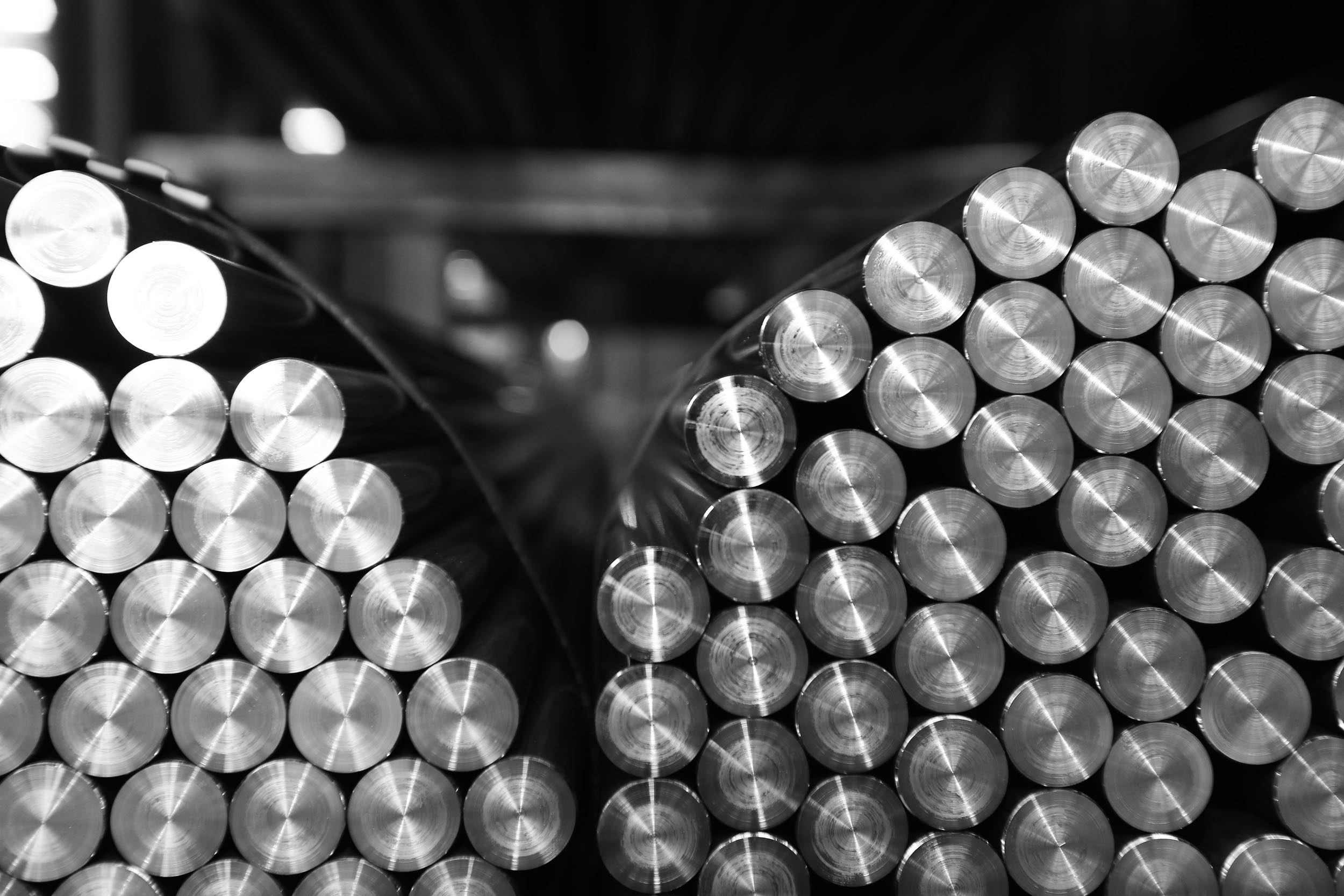

Figure 6: Induction hardened and tempered special steel, Source: Steeltec

About Steeltec

With a workforce of around 620 in six locations in Switzerland, Germany, Denmark, Sweden and Turkey, Steeltec is one of Europe’s leading manufacturers of special bright steels. Steeltec’s four self-owned production centres fabricate high-strength and higher strength special steel, high-quality bright steel, special quenched and tempered steel, free-cutting steel, case-hardening steel and engineering steel. Core areas of expertise include the application-specific development and production of high-quality bright steels, precision finishing operations and professional technical advice that is provided locally. Steeltec works closely with customers, suppliers and research institutions to continually improve the production and engineering properties of steel, driving competitiveness across the entire value chain. Thanks to its Europe-wide distribution network, Steeltec can guarantee delivery reliability to its customers in the automotive, hydraulic and mechanical engineering industries.

About SCHMOLZ + BICKENBACH

Today, the SCHMOLZ + BICKENBACH Group is one of the world’s leading providers of customised solutions in the specialty steel long products business. A global name in tool steel and stainless long steel, the Group is one of two largest companies in Europe for alloy and high-alloy engineering steel. With around 9.000 employees at its own production and distribution companies in over 30 countries across five continents, the Company supports and supplies customers wherever they operate. Besides the comprehensive Production and Sales & Services portfolio, customers benefit from the Company’s technological expertise, consistent high quality worldwide and in-depth knowledge of local markets.

Your contacts

Thorsten Müller • Steeltec Deutschland

Head of the Heat Treatment unit, Düsseldorf

Phone: +49 (0)211 509-2265 • Fax: +49 (0)211 509-1265

E-mail: thorsten.mueller(at)steeltec-group.com

Internet: www.steeltec-group.com

Guido Olschewski • Steeltec

Head of Management Systems and Product Development

Phone: +41 (0)41 209-5619 • Fax: +41 (0)41 209-5605

E-mail: guido.olschewski(at)steeltec-group.com

Internet: www.steeltec-group.com

Dr. Ulrich Steiner • SCHMOLZ + BICKENBACH

Phone: +41 (0) 41 581 4120

E-mail: u.steiner(at)schmolz-bickenbach.com

Internet: www.schmolz-bickenbach.com

External media contact

Katharina Scholten • additiv pr GmbH & Co. KG

Public relations for logistics, steel, industrial goods and IT

Graf-Adolf-Straße 72 • D-51065 Cologne, Germany

Telephone: +49 (0) 221 9647694-3

E-mail: ks(at)additiv-pr.de • Internet: www.additiv-pr.de